Enhance Well Stimulation with DiverterPlus

DiverterPlus technology is designed for optimizing well stimulation operations, addressing a wide range of challenges by supporting and improving performance in the following key areas:

(Click on down arrows to learn more about each of the aeras below)

NEAR WELLBORE DIVERSION (NWB)

Click here to learn more about our collaboration with Seismos to develop intelligent near wellbore diversion

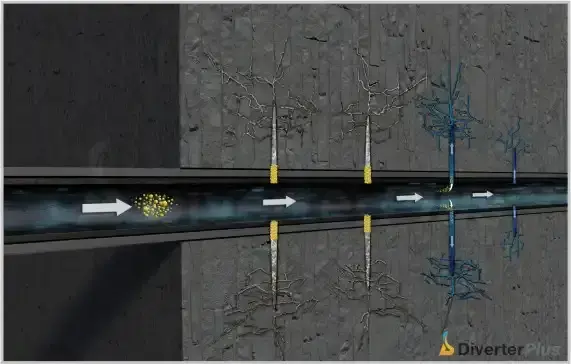

DiverterPlus NWB products are temporary diverting materials used to increase cluster efficiency and/or reduce stage count in fracturing treatments. During placement, DiverterPlus' products are solid non-toxic polymers capable of blocking perforation tunnels and fractures near the wellbore. After the product’s designed service life, the diverter will hydrolyze into a clear, non-hazardous liquid. This process is driven simply by time and bottom-hole temperature requiring no additional remedial work. DiverterPlus blends are unique multi-modal blends of particles for optimized transport and plugging performance.

Key Design Advantages

- Improved Perf/Cluster Efficiency

- Reduced/optimized Stage Count

- Controlled Fracture Geometry

- Low Viscosity Transport

Benefits and Outcomes

- Increased initial production

- Improved decline curve

- Reduced completion time

- Increased Stimulated Reservoir Volume

DiverterPlus specializes in tailoring the diversion package to your specific treatment and well conditions. By selecting from our versatile product portfolio and customizing deployment design, DiverterPlus consistently delivers optimal diversion results. Our customers can rely on our experience and expertise as we work handin-hand to optimize cluster efficiency and stimulation treatment distribution across the desired interval. In non-homogenous reservoirs, this can greatly increase stimulated reservoir volume. In relatively homogenous reservoirs, cluster efficiency can be increased to the point where multiple stages can be combined resulting in fewer plugs/stages, decreasing completion time and saving operators money.

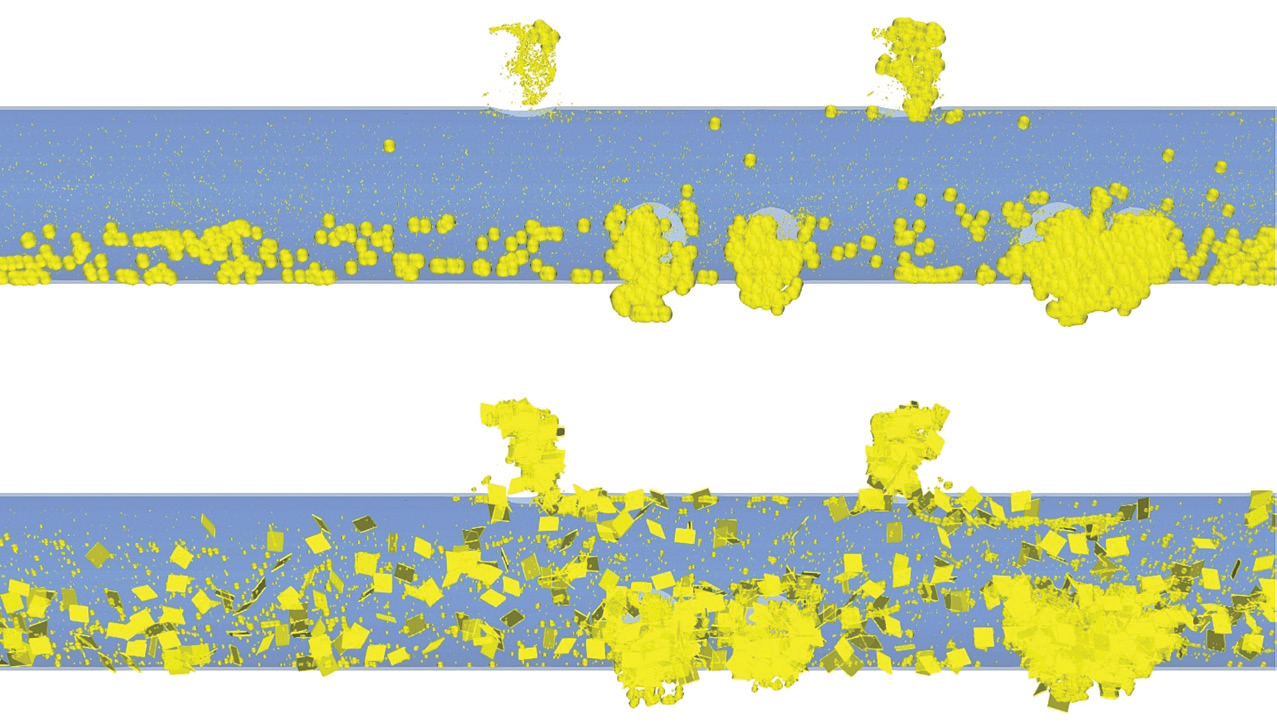

Improperly designed diverter treatments (top) result in uneven particle distribution resulting in perforation phase dependent diversion. Proper diverter design (bottom) provides efficient diversion regardless of perforation design.

FAR FIELD DIVERSION (FF)

Click here to learn more about the far field diversion case study

DiverterPlus' powders for use in far field applications are temporary diverting materials used to divert fracturing treatments. During placement, DiverterPlus' products are solid degradable polymer materials capable of arresting Fracture Half Length growth to generate fracture complexity. After successfully controlling fracture growth, the diverter is designed to hydrolyze to a clear, non-hazardous liquid. This process is driven simply by time, temperature, and pressure in the presence of water, meaning that no additional remedial work is necessary. DiverterPlus' powders are designed to be run in conjunction with proppant to facilitate the needed complexity generation and fracture geometry.

Key Design Advantages

- Improved Fracture Complexity

- Controlled Height Growth

- Long Distance Transport

- High Pressure Performance

Benefits and Outcomes

- Improved decline curve

- Increased Stimulated Reservoir Volume

- Optimized proppant placement

Complexity Generation

- Inducing tip screen outs re-orients individual conductivity paths such that the fracture network becomes more complex.

- The generation of new fracture tip azimuths results in increased reservoir contact within the same fracture perimeter.

- The primary fluid-taking fracture paths can be re-oriented in the far field to increase fracture complexity locally and establish permeability in previously un-contacted rock.

Zonal Migration Prevention

- Induce tip screen outs at the bedding plane(s) to limit height growth and prevent entrance into undesirable zones near target reservoir.

- Strategic use of mid-field and far-field diverters can compensate for regions of poor cement integrity or cement absence in order to preserve fracture isolation.

FAR FIELD DIVERSION (FF)

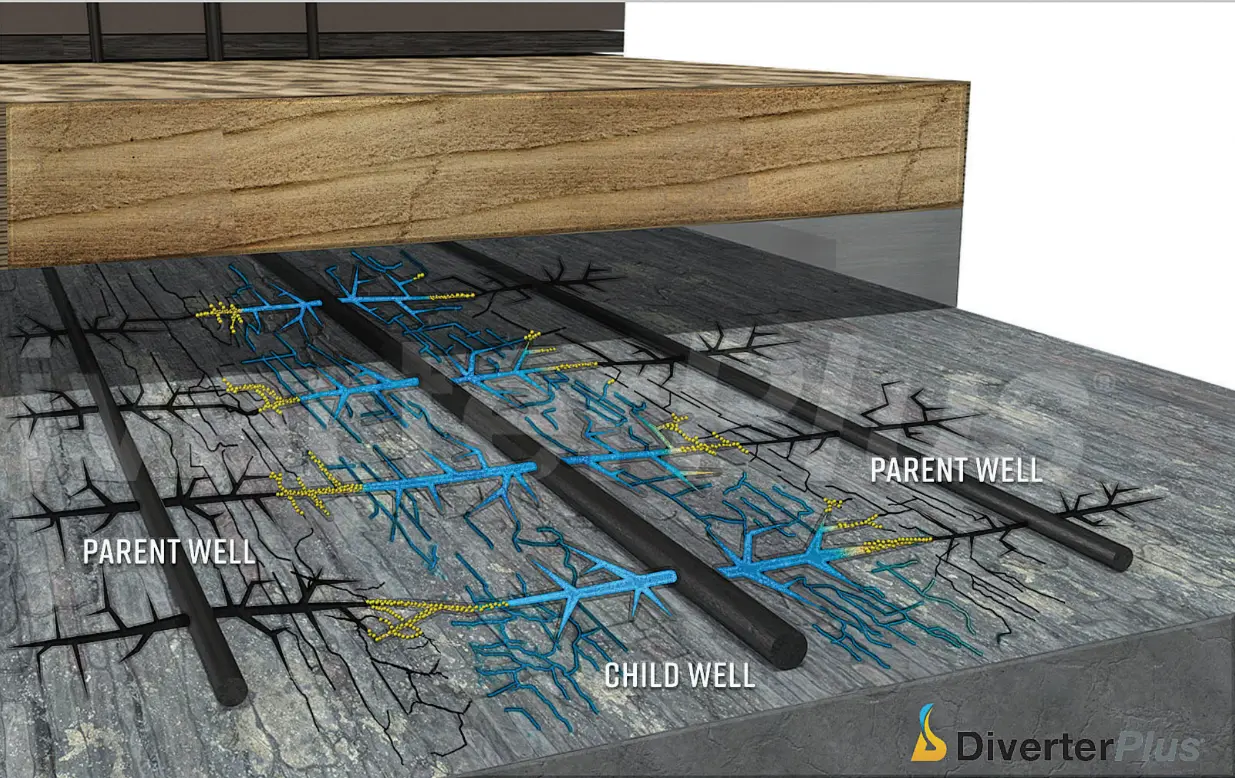

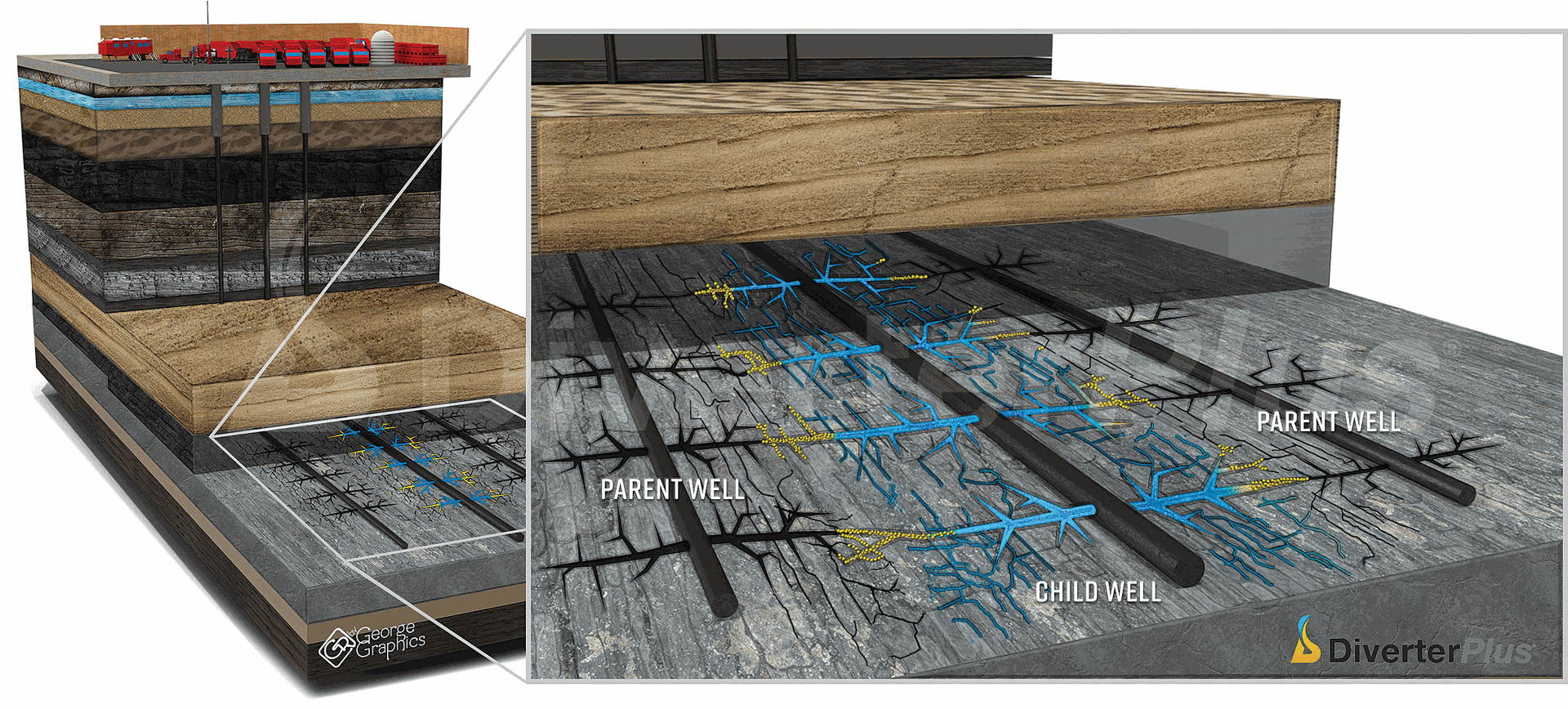

Div+ powders for use in far field applications are temporary diverting materials used to divert fracturing treatments. During placement, DiverterPlus is a solid degradable polymer material capable of arresting Fracture Half Length growth to mitigate Frac hits on offset wellbores as well as faults. After successfully controlling fracture growth, the diverter is designed to hydrolyze to a clear, non-hazardous liquid. This process is driven simply by time, temperature, and pressure in the presence of water, meaning that no additional remedial work is necessary. DiverterPlus powders are designed to be run in conjunction with proppant to

facilitate the needed limitation of fracture growth.

Key Design Advantages

- Improved proppant banking and settling

- Reorientation of fracture propagation

- Long Distance Transport

- High Pressure Performance

Frac Hit Mitigation

- Mixture with proppant creates a low permeability barrier that has the deformability to reach fracture tips and the strength to withstand tip pressures.

- By inducing tip screenout controls, in-situ fracture propagation is redirected such that fractures avoid reaching parent well reservoirs.

- Re-orienting fractures in the far field significantly reduces the frequency and intensity of frac hits.

- Due to operationally simple implementation, frac hits can be reduced with low cost and low risk.

Click here to learn more about our collaboration with WTC and DSO to develop tracer enhanced diverters

We’re committed to providing prompt and effective solutions to ensure your satisfaction.

Click here to learn more about our collaboration with WTC and DSO to develop tracer enhanced diverters

We’re committed to providing prompt and effective solutions to ensure your satisfaction.