*Click here to view a drilling case study in the Cardium Basin.

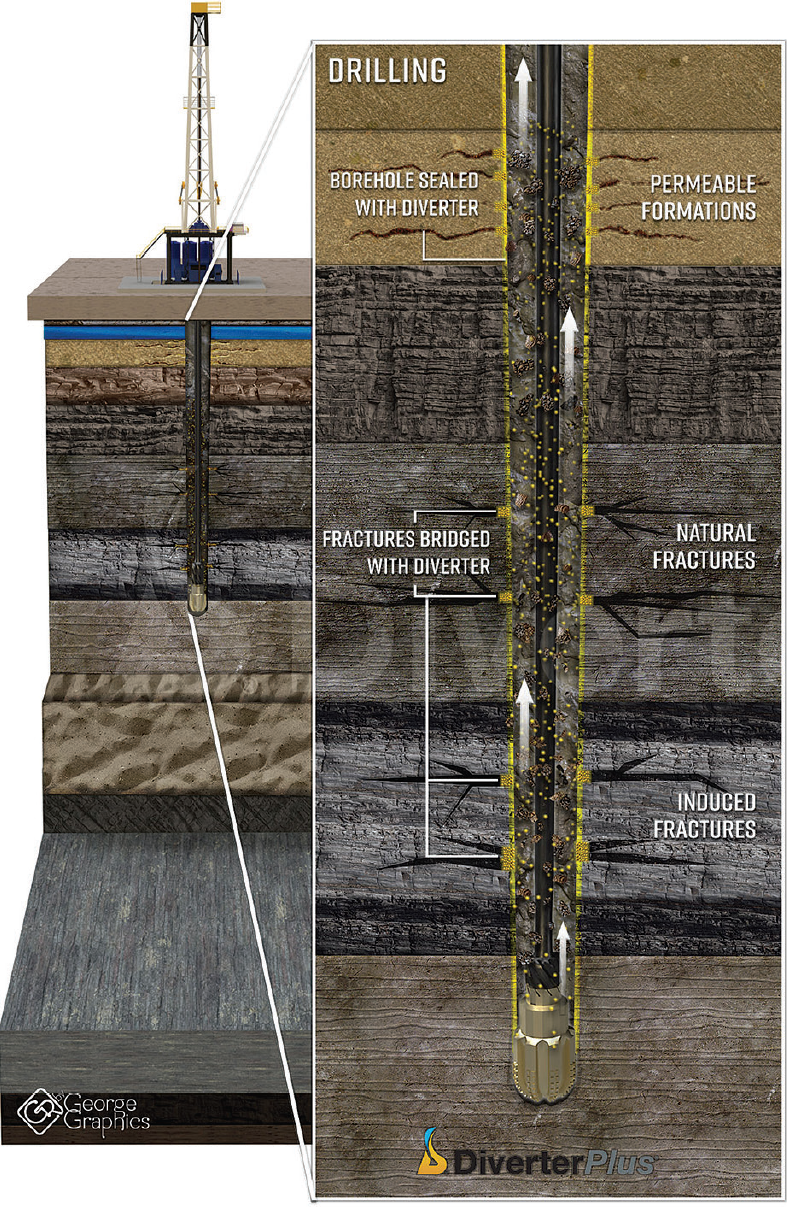

DiverterPlus drilling products are temporary diverting materials used to improve circulation and drilling efficiency. During placement, DiverterPlus is a solid degradable polymer material capable of bridging across highly permeable formations due to either high porosity, natural or induced fractures near the wellbore. After successfully plugging the loss zone(s), the diverter is designed to hydrolyze to a clear, non-hazardous liquid. This process is driven simply by time, temperature, and pressure in the presence of water meaning that no additional remedial work is necessary and no subsequent damages if deployed in reservoir sections.

Key Design Factors

Regain circulation in severe loss conditions

Reduced risk of formation damage when drilling in reservoir section.

Various deployment plans allow for tailored squeeze solutions, continuous circulation, or freeing stuck tubulars

Benefits and Outcomes

Minimal formation damage due to degradability of product

Reduced Mud Losses

Improved borehole Quality

A key component in improving drilling efficiency and controlling costs is stopping or preventing lost circulation. This is accomplished by the many available options of lost circulation material (LCM), however most LCM types available in the market today do not address the amount of formation damage or the negative impact on cement bonding they can cause. Through lab testing and field applications, degradable LCM has shown to be a cost-effective solution for not only stopping losses but also in addressing these two issues. DiverterPlus’ Cemvert+ line of products has proved to be effective for plugging various fracture widths at different temperatures while maintaining stability to cure losses then degraded over time to mitigate reservoir damage and improve cement bonding.