Optimizing Diverter and Trancer performance

(Permian Basin)

Goal: Improve monitoring of frac efficiency and fluid return dynamics to optimize production

Methodology: Analyzing tracers in diverters to track fluid movement, stage performance, and reservoir connectivity

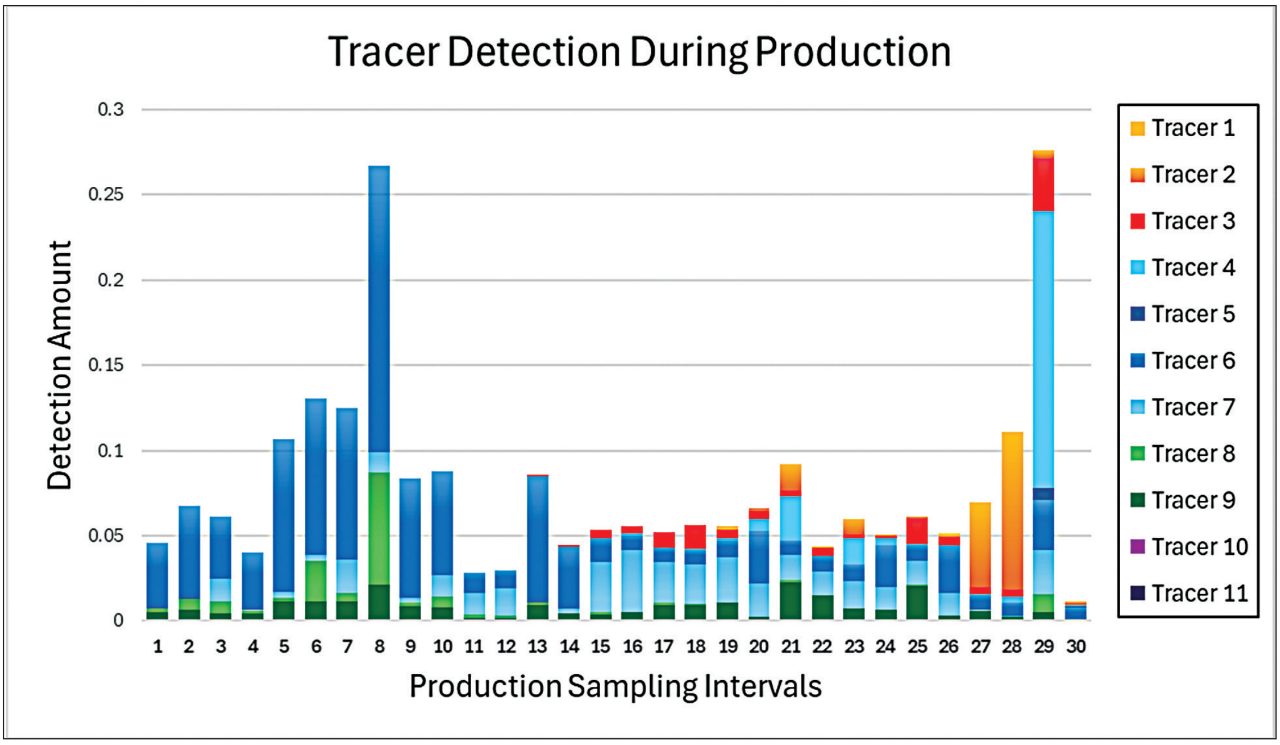

Operational Implementation: Tracers were deployed in various fracturing stages across multiple production intervals. Sampling of produced fluid was conducted at predefined time points to monitor tracer concentration.

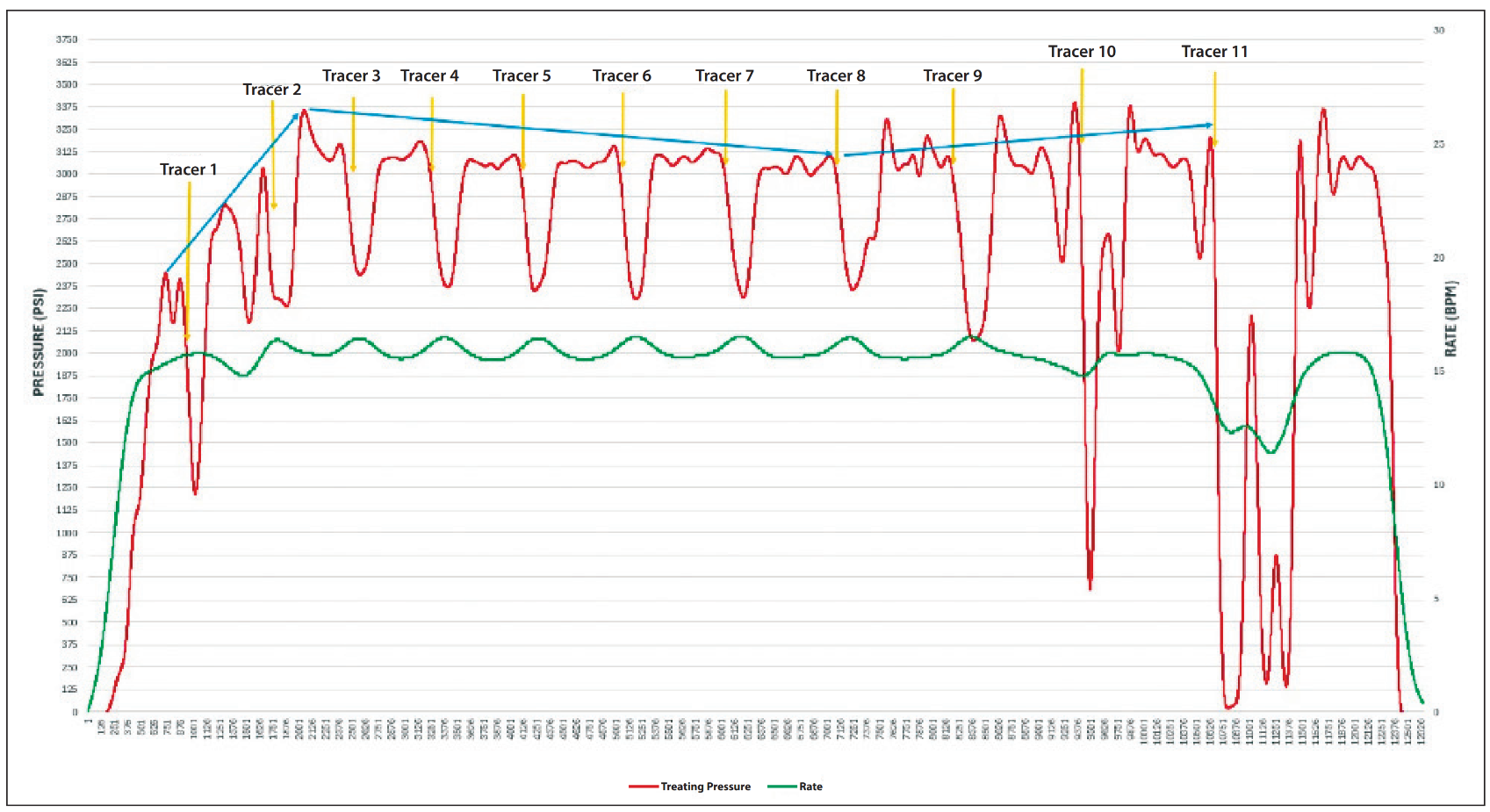

Data analysis and visualization: Data visualization tools, including time-series plots and comparative stage performance analysis, were used to analyze tracer distribution, peak response times, and dissipation patterns to evaluate stage contributions and fluid migration. Peak tracer concentrations were correlated with dissolution dynamics of the deployed diverters to determine optimal loading rates for maximizing efficiency.

Treatment Plot: (Yellow Arrows indicate Tracer-Embedded Diverter Pills)

Sampling of Production Flowback for Tracer Signatures

Results:

• Controlled tracer release via diverter degradation enables precise monitoring of stage efficiency.

• Peak tracer concentration indicates high-volume fluid movement stages.

• Diverter mass adjustments impact dissolution time and tracer detection. Proper diverter loading can optimize tracer performance and stage evaluation.

• Salinity variations influence tracer retention and response profiles.

• Production increased from 95 bbls/day to 275 bbls/day, demonstrating the effectiveness of optimized stimulation techniques