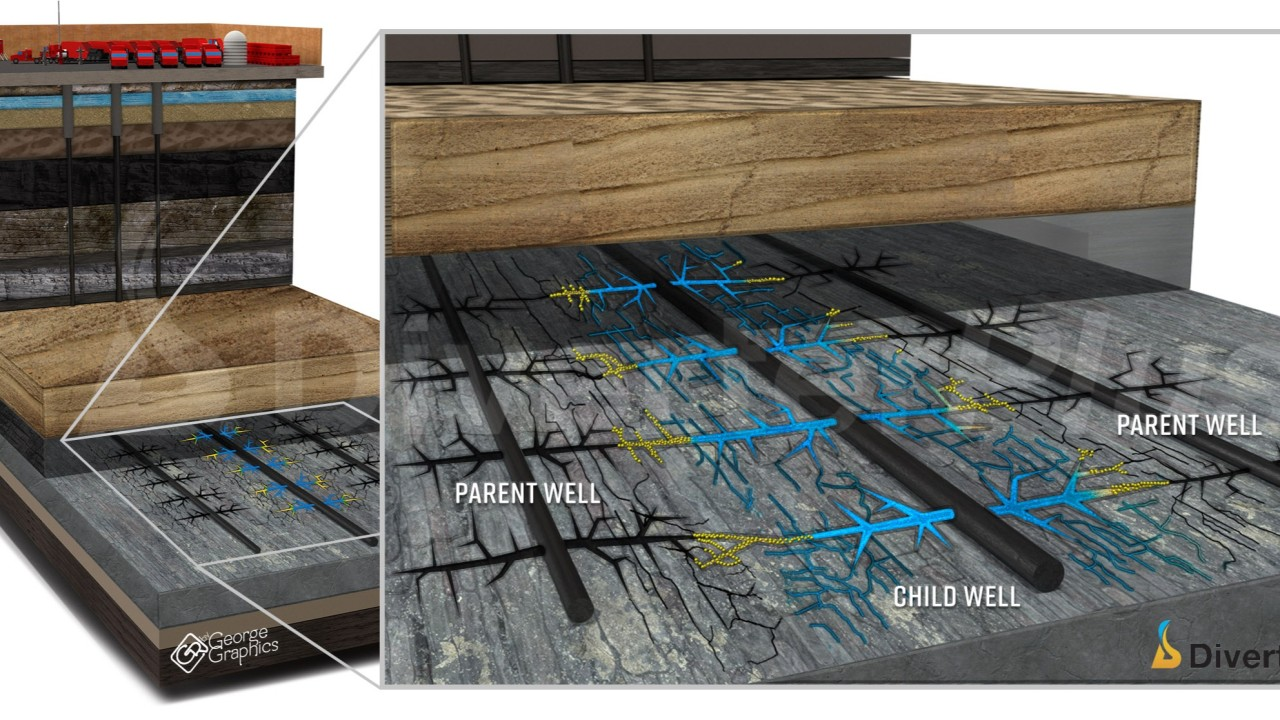

As unconventional developments mature, operators continue to face a familiar challenge: How do you increase production via increased fracture complexity while also protecting offset wells from fracture driven interactions (FDIs)?

Across multiple basins, Far-Field Diversion (FFD) is proving to be one of the most practical answers.

What is Far-Field Diversion?

Far-field diversion manipulates fracture geometry by depositing degradable materials near the fracture tip during propagation. By temporarily obstructing the fracture tip, the diverter redirects propagation into new directions - enhancing complexity, improving containment, and mitigating FDI risk.

Material Design and Deployment

Not all diverters behave the same. The right material balance between strength, transportability, and controlled degradation determines whether diversion helps or hurts performance.

At DiverterPlus, our far-field materials (e.g., CemVert+ D570, FF Black) are tested under field-specific pressure and temperature to ensure stability during treatment and complete degradation afterward.

Deployment methods include:

- Manual addition to the blender tub or hopper

- Proppant-belt integration for continuous dosing

- Last-mile container preloading (PropX, SandBox, etc.)

This makes FFD implementation operationally seamless.

How to Identify a Good FF Candidate

The best candidates are wells where operators seek to:

- Reduce frac hits and parent/child well interference

- Contain fracture height growth

- Improve reservoir coverage

- Reduce inter-stage interactions

Wells which consistently exhibit negative treating pressure trends experience the greatest production improvements.

Reading Diverter Response in Real Time

During pumping, pressure behavior tells the story. An effective far-field drop produces:

- A stabilized positive pressure trend without sharp spikes

- No abrupt pressure changes as diverter passes perforations

If the pressure trend fails to respond, the design can be adjusted on the fly by:

- Increasing diverter concentration

- Altering polymer composition

- Deploying smaller, more frequent drops

This real-time adaptability is where DiverterPlus real-time support provides measurable value.

Case Study: South Texas (Eagle Ford)

Objective: Increase fracture complexity for improved production. Two pairs of wells were completed with identical designs - one per pair with diverter, one without.

Results:

- +8% total production (BOE)

- +10% gas production

The takeaway: Strategic far-field diversion enhanced fracture geometry and overall production.

Case Study: Midland Basin

Objective: Reduce frac-driven interactions and maximize new-well productivity. FFD deployed on every stage of 92 infill wells, offsetting 83 parent wells.

Results:

- +20.5% 3-month production increase

- +19.7% 6-month production increase

FFD successfully limited parent well communication while improving early-time recovery - maximizing the impact of fracture treatments.

What’s Next: Tracer-Enabled Diverters

The next evolution in diversion is data-driven. DiverterPlus is now integrating DNA nanoparticle tracers directly into far-field materials - combining fracture control with stage-level diagnostics.

Two core applications:

- FDI Mitigation - Deploy rapidly degrading tracers (TraceVert™) before and after FFD to track parent-child well communication.

- Complexity Analysis - Embed tracers within the FFD itself to evaluate stage contribution, monitor production by interval, and optimize treatment sequencing.

This merging of diversion and diagnostics enables operators to see, for the first time, how fracture geometry translates into real production behavior.

Learn More

Watch our Wed(NSI)days presentation on Far Field Diversion

Join us at SPE ATCE 2025 – Booth #1423 📍 Oct 20–22 | Houston, TX

Featured Presentation: A Novel DNA Nanoparticle Tracer Technology in Diverter Applications for Optimizing Acid Stimulation Treatments 📅 Tuesday, Oct 21 | 8:30–11:30 AM | Room 320C